Ceramic heating elements

made of hotpressed silicon nitride ceramic

Chip heaters

miniature heaters made of silicon nitride

Products / Ceramic heating elements / Chip heaters

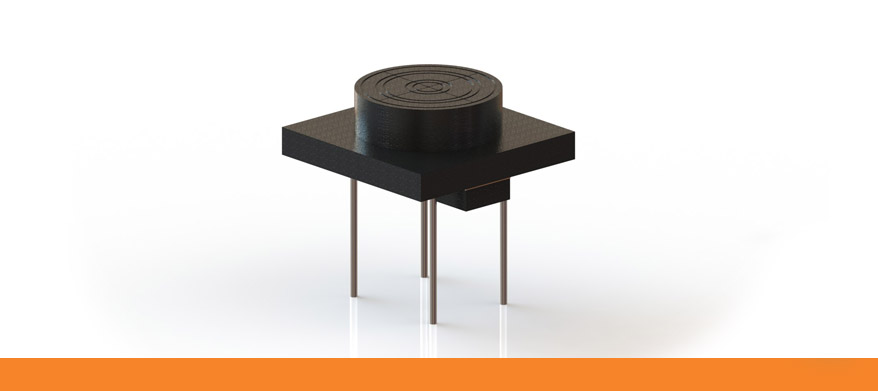

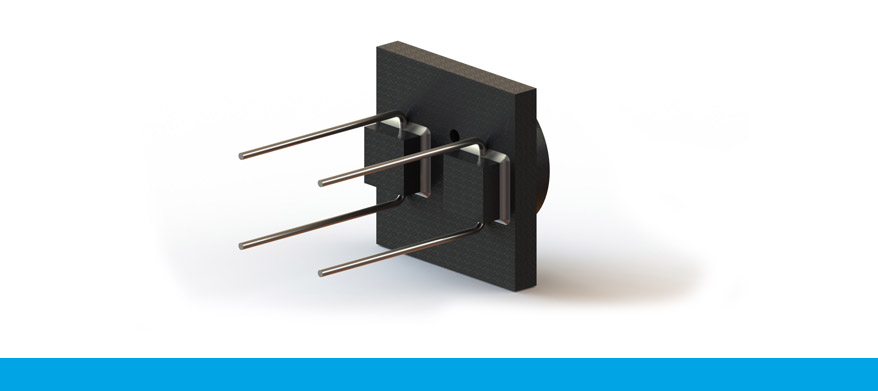

Chip heaters

Description

Chip heaters made of silicon nitride are normally rectangular. Various dimensions and batch sizes up to our die diameter of 400 mm can be produced. The special properties and the low mass of ceramic allow fast heating rates, a uniform temperature distribution and high control accuracy. Small heating elements can be operated controlled with very high surface power at short cycle times. In comparison to metal the surface of ceramic stays very smooth due to its low thermal expansion even when operated with changes in temperature. The high strength of hot-pressed silicon nitride guarantees high stress resistance (e. g. with high pressure loads) and excellent wear resistance. We provide miniature heaters for operating in the open air at temperatures up to 500 °C and heaters with a cold area at temperatures up to 1 000 °C.

Customized design

Our in-house designs make any modification in size, configuration, or performance simple and convenient. Mounting-bracket holes and bores for temperature sensors or suction pipes can be included. Laser-cut vacuum grooves can be added as well. Our chip heaters come already flat ground, however they can be ground further up to a flatness of < 10 μm to meet specific requirements. A variety of shapes formed to the contour of the element to be heated are possible as well. They can be produced as a point (point heaters) or as protruding flat. Thus heated areas with a size of < 1 mm2 are possible. Miniature heaters can be converted to be operated on low voltage

Range of products

This is only a small selection from our product portfolio. For other variants please contact us with our product request form.

| Dimensions | Heated area | Tmax |

|---|---|---|

| 10 x 4.0 x 4.0 mm | 10 x 4.0 x 4.0 mm | 500 °C |

| 36 x 35 x 3.5 mm | 36 x 35 x 3.5 mm | 500 °C |

Advantages

Your advantages:

- You can generate the heat exactly at the spot where it is needed

- Fast heating rates reduce processing time and increase Your yield through shorter cycle times

- The inert and chemically resistant ceramic material avoids any contamination of your system

- High specific power up to 150 W/cm2

Areas of application

- semiconductor processing systems (e. g. die bonders)

- handling of components, assembly of printed circuit boards (PCBs)

- soldering systems and desoldering equipment

- nozzle heaters

- packaging machines (e. g. point-by-point welding)

- medical technology

- machine-building

- tool heating